Performance description:

The tubular conveyor belt is an environment-friendly conveyor belt. When conveying materials, the belt is sealed in a tubular shape, and the transportation is dust-free, leak-free and pollution-free, with wear-resistant, heat-resistant, cold-resistant, chemical corrosion resistance, flame retardant, anti-static properties.

Classification:

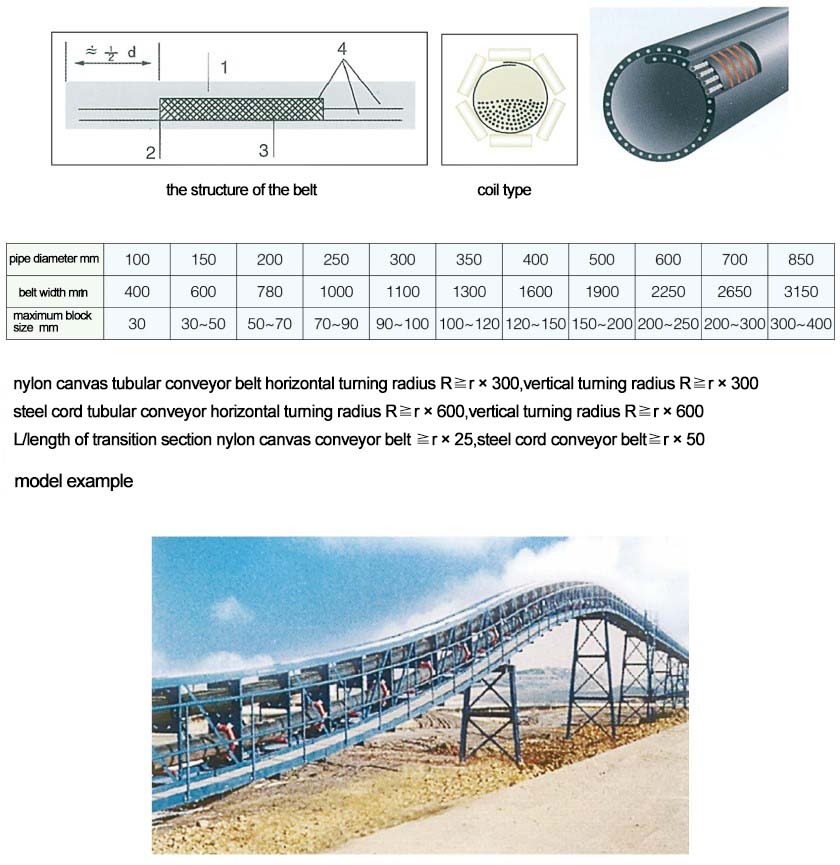

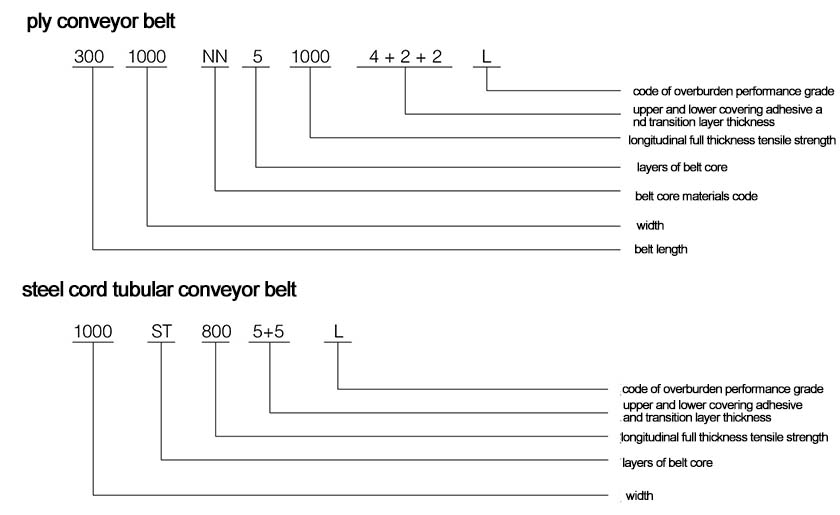

According to the framework layer structure can be divided into fabric core tube conveyor belt and steel cord core tube conveyor belt.

Compared with the traditional steel cord conveyor belt

The steel cord conveyor belt has better tube forming performance, will not appear the defects of tube collapse, tube expansion and tube type torsion, and can ensure the best transport environment for customers.

canvas core pipe conveyor belt

The framework of the force-bearing material is single-layer or multi-layer chemical fiber, both sides of the belt body adopt special production technology, so that the finished product has proper lateral rigidity, easy to pipe and not fatigue. It is used in cement plant, dock, power plant, fertilizer plant, etc. .

Market: Gathering and distribution occasions, cement, quarries, power plants, steel mills.

Application: main conveying line, long distance conveying, roadway conveying, inclined conveying, other demanding conveying.

Nominal Diameter Of Tube: 100 ~ 600 mm.

Uses:widely used in metallurgy, electric power, chemical industry, ports, docks, building materials, coal, mines, grain and other industries bulk materials airtight transportation.

Features: Airtight conveying, bending conveying, large angle conveying, reciprocating conveying, high-speed and high-load conveying.

Notes on the use of conveyor belts:

1. Do not connect different varieties, models, specifications of conveyor belts together

2. Conveyor belt should be carefully checked as required before starting

3. Run tension do not exceed the conveyor belt design tension and avoid overloading

4. Adjust the cleaning device and scraper, avoid wear conveyor belt, avoid oil or grease and other debris bonded to the conveyor belt and support roller or roller

5. Avoid sunlight causing the conveyor belt to age as much as possible after rain and snow

6. Avoid using gas cutters or welding machines around conveyor belts to prevent damage to conveyor belts

7. When conveyor belt has damage should be repaired in a timely manner

8. The feed direction shall be consistent with the direction of operation of the conveyor belt, and the feed should be uniform to avoid excessive local load

9. Minimize the drop of material

10. The connector direction should be consistent with the running direction when bonding to avoid damage to the connector by the material and scraper